聚光灯

Maintenance Technician, Industrial Mechanic, Maintenance Mechanic, Facilities Technician, Equipment Technician, Plant Maintenance Technician, Maintenance Engineer, Maintenance Electrician, Machine Repair Technician, Service Technician, Automated Manufacturing Technician

Roughly 75% of the goods we use are made with the help of industrial machines or processes. From electronics, appliances, and vehicles to furniture, clothing, and toys, we rely on things made by complex machines!

But these machines need constant maintenance to operate efficiently; otherwise, their parts can wear out quickly or they can simply break down. If one machine stops working, it can create a bottleneck that grinds the entire manufacturing process to a halt. When that happens, it’s very expensive for the company, which must pay workers to wait around while that machine gets fixed.

Such unplanned downtime can “cost a company as much as $260,000 an hour,” according to Aberdeen Research. So it’s no wonder why companies rely on Industrial Maintenance Technicians to ensure operations run smoothly.

The technicians inspect machines and equipment, perform preventative maintenance, and make minor repairs as needed to minimize downtown and maximize productivity. Their work can save companies millions of dollars a year!

- Ensuring smooth and efficient operation of industrial equipment

- Reducing downtime and increasing productivity

- Being a crucial part of the production process

- Helping companies maintain profitability so they can stay in business

工作日程

- Industrial Maintenance Technicians work full-time, including shifts that cover nights, weekends, and holidays. Overtime is sometimes required, especially during peak production periods or when urgent repairs are needed.

典型职责

- Perform routine inspections to ensure machinery is in good working order

- Use hand and power tools to conduct preventive maintenance aimed at preventing breakdowns

- Check equipment fluid levels, as necessary

- Clean, lubricate, and make minor adjustments to machinery, in accordance with manufacturer guidelines

- Use diagnostic equipment to troubleshoot mechanical, electrical, and hydraulic issues

- Repair or replace defective, damaged, or worn out parts.

- Maintain parts inventories

- Fabricate or grind parts to fit dimensions

- Perform basic wiring and welding as required

- Collaborate with other maintenance staff and production team members

- Assist in the installation of new equipment and machinery, following manufacturer specifications

- Calibrate and test equipment, if authorized to do so, to ensure optimal operation

- Provide training to junior technicians and machine operators

- Keep records of maintenance activities and issues on logs and work orders

- Ensure compliance with safety regulations and standards to avoid workplace injuries

- 标记正在维修或等待零件的设备

- 拆卸需要移动或运离现场的部件

- 拆卸时仔细编目

额外责任

- Order supplies

- Prepare cost estimates

- Review technical manuals as needed

- 清点工具和设备

- 在使用测试工具测试机器之前,确保正确校准所有测试工具

- 准备和使用化学清洁产品

- 执行所有安全协议,减少工作场所事故

- 根据需要佩戴适当的个人防护设备

- Report machinery statuses and maintenance activities to supervisors

- Suggest improvements to enhance equipment performance and reliability

- Stay up-to-date on maintenance techniques, tools, and relevant software

软技能

- 适应性

- 分析性的

- 注重细节

- 协调

- Evaluation skills

- 手和手指的灵活性

- 独立的

- 观察者

- 组织机构

- 耐心

- 解决问题

- 现实的

- 力量和耐力

- 阅读能力强

- 团队成员

- 时间管理

技术技能

Industrial Maintenance Technicians must be familiar with:

- Computerized maintenance management systems

- Diagnostic and precision tools

- 设备维护、校准和维修

- 设施管理计划

- Industrial safety regulations

- 库存管理软件

- Mechanical and electrical systems

- Programmable logic controllers

- 技术手册数据库

- Technical manuals and blueprints

- Tools and equipment usage

- Welding and machining

- Automotive factories

- 商业和工业维修

- 建筑

- Energy production facilities

- Food processing facilities

- Manufacturing plants

- Pharmaceutical plants

- 批发贸易

The role of Industrial Maintenance Technicians involves physical labor, working in confined spaces, and being exposed to workplace hazards like noise, smoke, fumes, moving parts, and sharp metal.

Technicians have to stay vigilant to avoid mishaps. They’ve also got to be very knowledgeable about the machines and equipment they work on, so they can keep everything up and running as much as possible.

Since downtime due to breakdowns can be so costly, a lot is riding on the diligence of these workers. They simply can’t afford to lose track of maintenance schedules or to forget to perform some critical preventive fix. When something does go wrong, they’ve got to be ready to address it immediately – or know who to contact to do repairs beyond their scope of duty!

With advancements in technology, Industrial Maintenance Technicians are increasingly expected to work with sophisticated diagnostic tools and automated machinery.

Predictive maintenance, which uses data analytics to predict equipment failures before they occur, is getting more common every year. Technicians thus have to develop skills in data analysis and digital tools.

At the same time, the rise of automation and smart factories means that Industrial Maintenance Technicians need to be very familiar with programmable logic controllers and other automated systems. This shift is creating new opportunities for those who can combine traditional mechanical skills with knowledge of advanced technology.

Many Industrial Maintenance Technicians enjoyed tinkering with mechanical devices, fixing bikes, or disassembling gadgets to see how they work. They often had a natural curiosity about how things function, as well as a general knack for problem-solving. High school shop classes, science fairs, and hands-on projects likely played a significant role in their early interest in this career field!

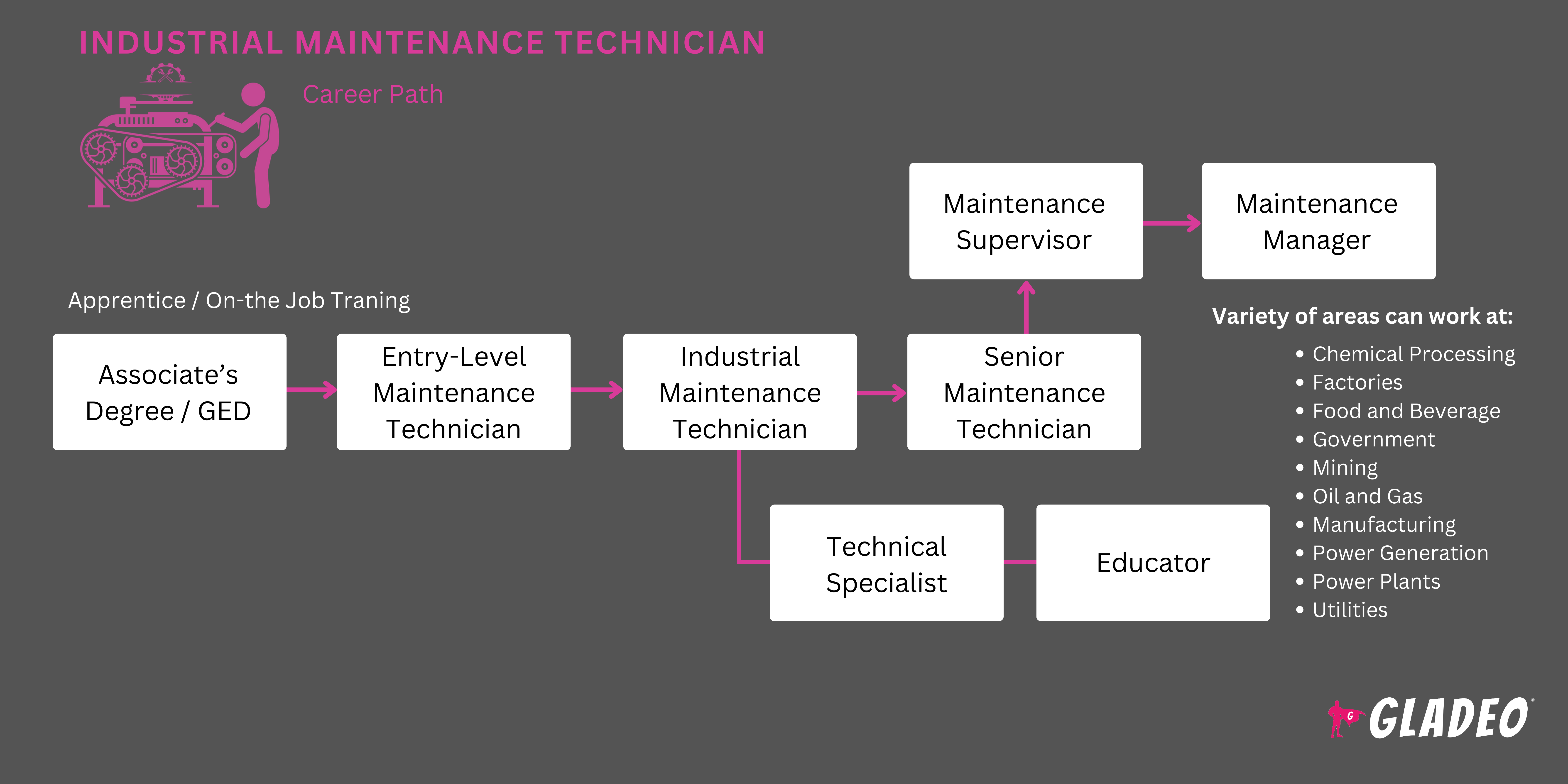

- Industrial Maintenance Technicians need a high school diploma or equivalent. A college degree isn’t required

- Many technicians get started through apprenticeship programs. Some can get hired if they have sufficient relevant experience, and then they just receive On-the-Job training for job-specific tasks

- Community colleges and technical schools offer certificates or associate degrees in industrial maintenance, mechatronics, and related fields. These can make applicants more competitive and help them qualify for more job opportunities

- Relevant educational coursework includes topics such:

1. Automation and Control Systems

2. Blueprint Reading

3. Computer-Aided Design

4. Electrical Systems

5. Energy Management Systems

6. HVAC Systems

7. Hydraulics and Pneumatics

8. Industrial Electronics and Robotics

9. Instrumentation and Measurement

10. Machine Tool Technology

11. Material Science And Metallurgy

12. Mechanical Systems

13. Preventive Maintenance Strategies

14. Process Control Systems

15. Programmable Logic Controllers

16. Welding

- Some employers require applicants to be certified through organizations like the Society for Maintenance & Reliability Professionals’ Certified Maintenance and Reliability Technician (CMRT)

- The CMRT exam contains 175 multiple-choice questions and can be taken at over 5,500 testing centers

- “The CMRT exam tests competency and knowledge of specific tasks within four domains: Maintenance Practices, Preventative and Predictive Maintenance, Troubleshooting and Analysis, and Corrective Maintenance,” per SMRP

- As of 2024, the exam fee cost for SMRP members is $300; for non-members, it’s $470

- Other popular certifications include:

- International Council for Machinery Lubrication - Machine Lubricant Analyst or Technician

- International Fluid Power Society - Fluid Power Mobile Hydraulic Technician

- Packaging Machinery Manufacturing Institute - Mechatronics: Fluid Power 1

- Occupational Safety and Health Administration (OSHA) - Hand and Power Tools and general industry courses

- Due to the importance of the role, technicians might also need to pass a background check and have a valid driver’s license, so they can respond to an after-hours emergency

- A four-year degree is not needed, but students can take preparatory college classes at a community college or vocational school.

- Look for accredited programs with plenty of hands-on training components, as well as internships or cooperative education experiences.

- 比较学杂费,注意州内与州外的费用。

- 查看奖学金和经济援助选项。

- Check out job placement statistics for students who complete the programs.

- If applying for federal aid Pell Grants, make sure the money can be used to pay the tuition at your particular school of interest.

- Veterans can look for military-friendly schools that have VA benefit experts to help navigate the system.

- Take applicable classes to learn about simple programming, welding, safe use of hand tools, hydraulics and pneumatics, reading blueprints, doing shop math, and working on electronics

- Get all the practical experience as you can at school and through part-time jobs or apprenticeships

- Talk with technicians to learn about their day-to-day work activities

- Watch YouTube videos and read articles about industrial maintenance

- Consider extracurricular activities like robotics clubs

- Pursue a relevant technical training program after finishing high school

- Build a network of industry contacts and keep in touch with them

- Review job ads on sites like ZipRecruiter, SimplyHired, Indeed, Monster, and Glassdoor

- Read the required and preferred skills listed in the job ads

- Pay attention to the keywords used in job ads, and use them in your resume. Keywords might include:

- 蓝图阅读

- CMMS (Computerized Maintenance Management Systems)

- Diagnostics

- Electrical Systems

- Equipment Installation

- HVAC Systems

- Hydraulics

- 库存管理

- Lean Manufacturing

- Machine Calibration

- Mechanical Repair

- OSHA Compliance

- PLC Programming (Programmable Logic Controllers)

- Pneumatics

- Predictive Maintenance

- Preventive Maintenance

- Root Cause Analysis

- 安全协议

- Welding and Fabrication

- If applying for an apprenticeship, list any related work experience or skills on your application

- 考虑为手工工具或一般行业进行 OSHA 认证

- Ask people in your network to let you know if they hear about job openings

- Attend job fairs and industry events to connect with potential employers

- Ask previous supervisors or teachers to write recommendation letters or request their consent (in advance) to list them as references

- 在面试中,表现出对行业趋势的敏锐认识

- Review resume templates for Industrial Maintenance Technician and check out sample interview questions

- Run through some mock interviews with friends or your school’s career center

- 面试时穿着专业

- Let your supervisor know you’re interested in growth opportunities when the time is right. Focus first on the job you were hired for and share your willingness to learn and advance

- Master your duties then keep learning more! Take advanced courses or complete specialized certifications

- 向设备和机器制造商了解您应该熟悉的趋势和新发展。他们很乐意与你交流!

- Use downtime to study technical manuals

- Be proactive. Look up answers for yourself but ask questions if something is unclear or you need a hands-on demonstration. Seek out mentorship but prove you can do the work on your own, without assistance

- 正确地培训他人,因为如果他们犯错,就会影响到你对他们的培训

- Stress safety and compliance at all times. Be a workplace leader and set an example!

- Earn a reputation as someone who is reliable and gets the job done right

- Join professional organizations such as the Society for Maintenance & Reliability Professionals to grow your network and discover new opportunities

- 了解最新的监管变化,确保您的组织始终合规

网站

- 美国总承包商协会

- 国际机械师和航空航天工人协会

- 国际电气工人兄弟会

- 国际机械润滑理事会

- 国际流体动力学会

- 国际自动化学会

- Industrial Supply Association

- 全国制造商协会

- 国家工程技术认证研究所

- 国家工具和加工协会

- 职业安全与健康管理局

- Packaging Machinery Manufacturing Institute

- 精密机械加工产品协会

- 维护与可靠性专业人员协会

- 美国木匠和细木工联合兄弟会

- 钢铁工人联合会

书籍

- Industrial Maintenance, by Michael E. Brumbach and Jeffrey A. Clade

- Industrial Mechanics and Maintenance, by Larry Chastain

- Machinery’s Handbook Toolbox, by Erik Oberg

- Maintenance Fundamentals, by R. Keith Mobley

- Reliability-Centered Maintenance, by John Moubray

Industrial Maintenance Technicians are key players in any manufacturing facility. But if you’re curious about other occupations that require similar skills, check out our list below!

- Automotive Service Technician and Mechanic

- 锅炉操作员

- Control and Valve Installer

- 电气与电子工程师

- 电工

- Electric Motor Repairer

- Facility Maintenance Manager

- 暖通空调技术员

- Industrial Engineering Technologist

- 工业机械技师

- Machine Feeder

- 机械师

- 机械工程师

- 医疗设备修理工

- Mobile Heavy Equipment Mechanic

- 水管工、管道工和蒸汽设备工

- Production Supervisor

- Rail Car Repairer

- Tool Grinder

- 焊工

- 风力涡轮机技术员

- Woodworking Machine Setter

新闻联播

特色工作

在线课程和工具

年薪预期

New workers start around $62K. Median pay is $77K per year. Highly experienced workers can earn around $109K.